Before each product is delivered to the customer, we will test each item of the product. Testing targets that are generally not taken seriously by manufacturers will be a must-inspection item at Hot Display, because we are committed to improving product quality. Raise to the maximum.

Before leaving the factory, our testing items include but are not limited to the following reliability tests:

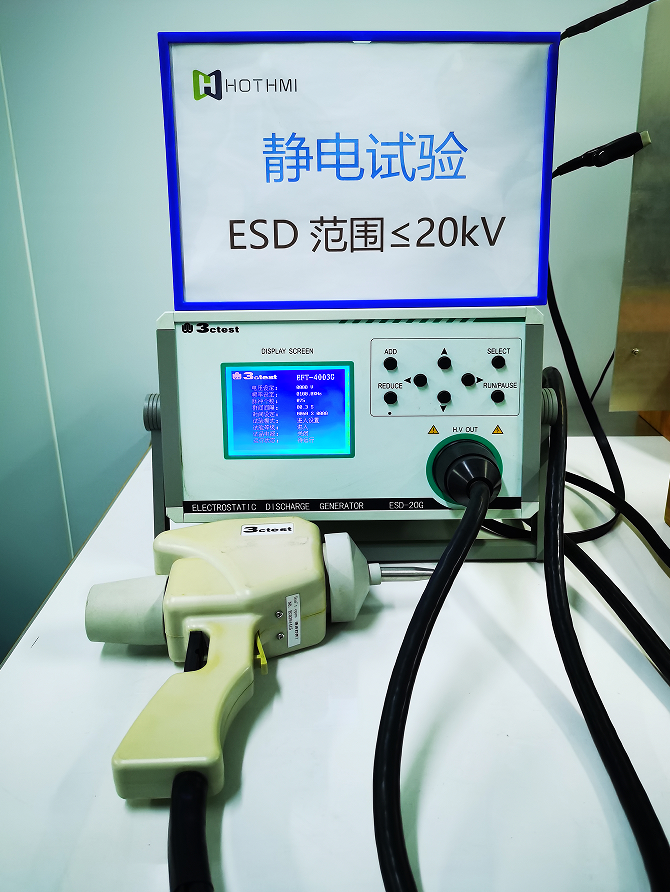

Electrostatic test (ESD):

Electrostatic discharge (ESD) testing is used to test the ESD resistance of ICs and electronic devices.

ESD, also known as electrostatic discharge testing, is a procedure used to evaluate the ability of electronic equipment to withstand and dissipate electrostatic discharge. This testing typically involves subjecting the device to a high-voltage discharge via contact or air discharge and measuring the resulting current and voltage. The device is then evaluated based on whether it continues to function properly after discharge. ESD testing is very important during the product development process of electronic devices, especially those that are sensitive to electrostatic discharge, to ensure that they can withstand the various electrostatic events that may be encountered in the real world and meet regulatory requirements for safety and performance.

Static electricity test bench

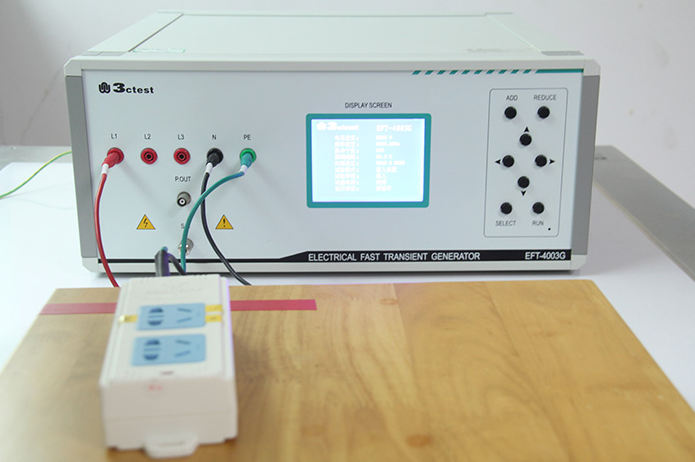

Group pulse EFT test

EFT (Electrical Fast Transient) testing is an important part of electromagnetic compatibility testing. It focuses on transient voltage disturbances on power lines. The EFT test simulates the situation when the device encounters transient interference on the power line by injecting short pulse signals into the power line. This transient interference may be caused by lightning strikes, power switches, motor starts, etc.

The essence of EFT testing is to verify the device's resistance to such transient interference.

Group pulse EFT tester

Vibration test

The purpose of the vibration test is to simulate a series of vibration phenomena, test whether the product can withstand the test of the vibration environment during transportation or use during the life cycle, and also determine the requirements for product design and function. The essence of the vibration test is to confirm the reliability of the product, screen out defective products in advance before leaving the factory, and evaluate the failure analysis of the defective products to make them high-level, high-reliability products.

Vibration test bench

High and low temperature impact test

High and low temperature impact tests are mainly suitable for climate and environmental change performance tests of electronic components, communication products, and automotive parts, and provide environmental reliability tests, product screening tests, etc. At the same time, by conducting high and low temperature impact tests, product reliability can be improved and product quality can be controlled.

High and low temperature impact test chamber

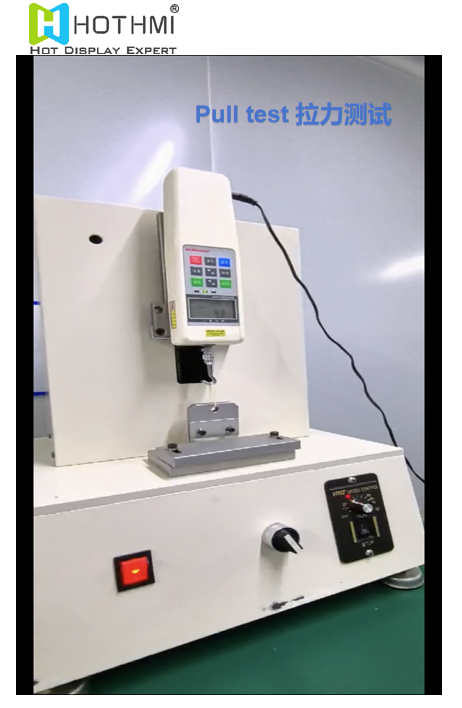

Pull test

The pull test can test the maximum pulling force between the cable and the glass after it is bound to the LCD glass. This value is very important for engineers when designing products, because if the pulling force is not up to standard, when the display is bound to the product, it will easily be too stressed and the circuit will be blocked and the display will be abnormal!

PULL Testing instrument

Product aging test

Aging detection is a process of simulating various factors involved in the actual use conditions of the product to perform corresponding condition-strengthening experiments on the aging of the product.

Product aging test rack

Tensile test

The tensile test can test the maximum pulling force between the cable and the LCD glass after it is bound to the LCD glass. This value is very important for engineers when designing products, because if the tensile force does not meet the standard, when the display is bound to the product, it will be easy to be overstressed, causing the circuit to be blocked and display abnormality!

Tensile tester

For more information,Please contact with us!