Functional chips, also called sensors, are one of the components in the manufacturing process of touch screens. It is a touch switch module based on capacitive sensing. When the human body or metal directly touches the metal surface on the sensor, it can be sensed. In addition to directly touching the metal surface, it can also be sensed through a certain thickness of plastic, glass and other materials. Xinhongtai Technology can "tailor-make" functional chips for products according to the needs of different products.

1. Customized functional sheet material: glass material or Film (film, film, film) material

(Hot Display Customized Functional Chip)

2. Customized functional sheet thickness: (mm)

0.3/0.4/0.55/0.7/1.0/1.1 (mm) etc.

(0.55mm, 0.7mm, 1.1mm are the most commonly used thicknesses)

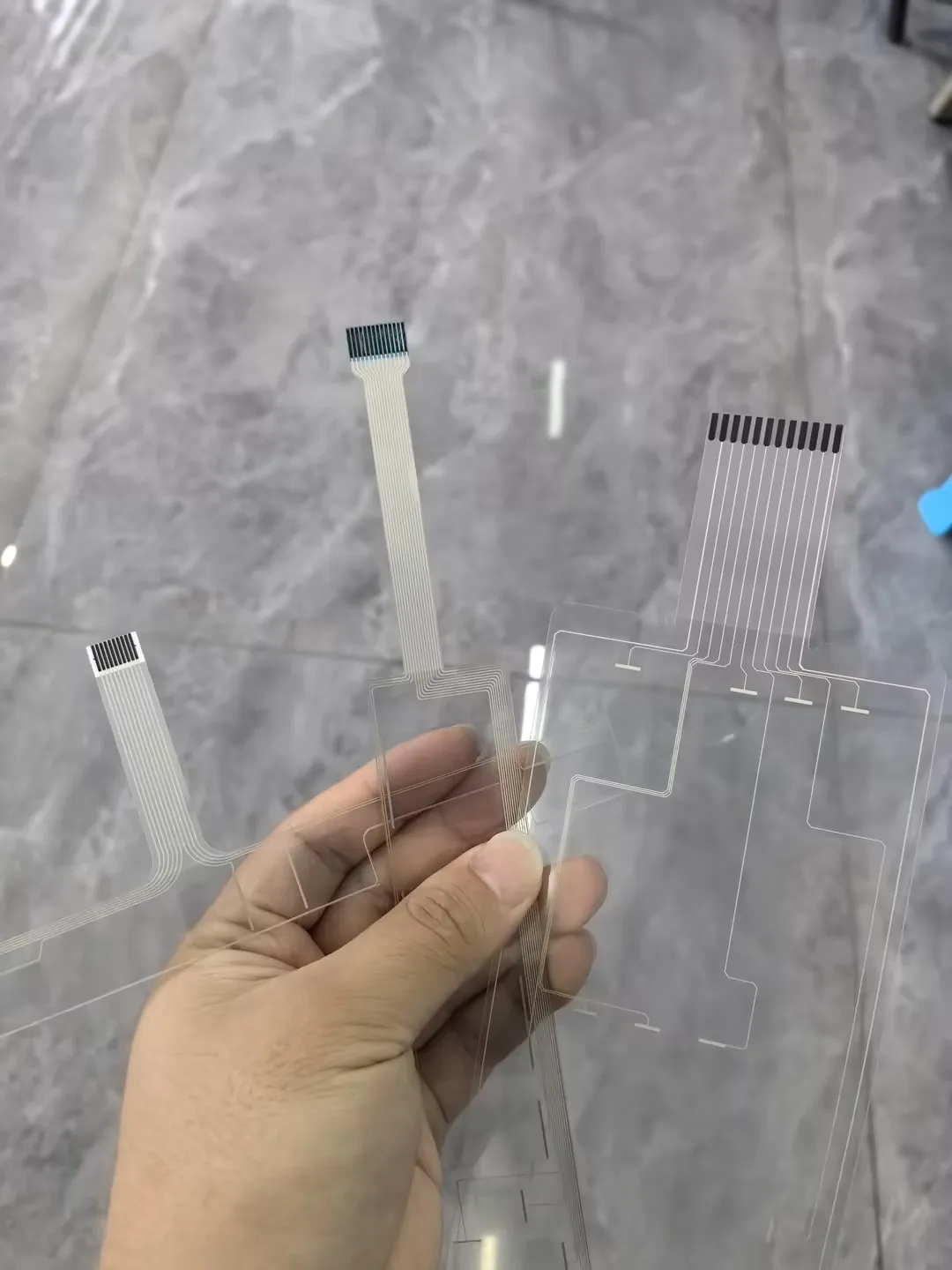

3. Customized FPC position: The wire can be connected at any position according to the customer's product requirements. 4. FPC shape: The appearance is flexibly designed according to the user's structure. 5. Interface support: IIC / SPI / USB / RS232, etc.

4. FPC shape: The appearance can be flexibly designed according to the user's structure.

5. Interface support: IIC / SPI / USB / RS232, etc.

6. Functional film knowledge expansion:

First, let's understand what ITO is? ITO film is an n-type semiconductor material with high conductivity, high visible light transmittance, high mechanical hardness and good chemical stability. It is the most commonly used film material for transparent electrodes of liquid crystal displays (LCDs), plasma displays (PDPs), electroluminescent displays (EL/OLEDs), touch panels (TouchPanels), solar cells and other electronic instruments.

Integrated functional sheet: also known as integrated PIN sensor. It refers to a sensor that combines ITO film and communication interface into one. For touch screens, when a touch occurs, the electrical signal needs to be conducted through ITO (conductive film) to the electronic components that can convert the electrical signal for centralized processing. The resistance of the ITO film has resistance. When these electrical signals are over a long distance in the ITO film, the greater the distance, the greater the resistance. In other words, when the electrical signal reaches the communication interface from the touch point, the electrical signal becomes extremely weak due to the excessive resistance. The changed electrical signal will convey wrong information, and even cannot transmit the information to related electronic components (such as chips). The result is: the touch cannot transmit the signal, or transmits the wrong signal.

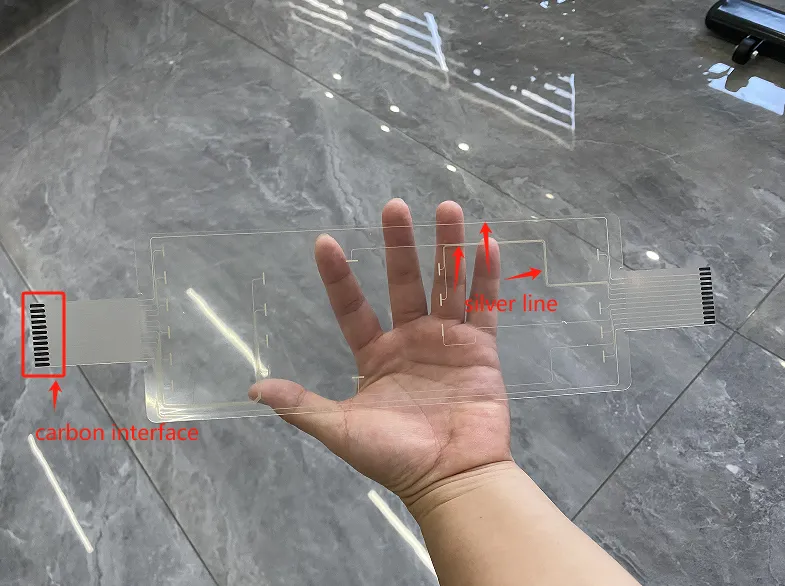

Solution: Use silver wire instead of ITO as the conductor for transmission on the ITO film. The resistance of silver is much smaller than that of ITO. Using silver as a conductive carrier can greatly reduce the resistance of the signal during transmission, so that when it reaches the cable interface, the electrical signal does not change, and finally accurately transmits the signal to the chip, and the processed electrical signal will respond accurately accordingly.

Advantages and disadvantages of integrated functional sheets:

Advantages: This integrated functional sheet has a simple structure, cheap materials, and high cost performance, and is the choice of many touch screens.

Disadvantages: It needs to be combined with silver wire as a transmission conductor. The silver wire can be seen on the film, and it cannot be fully transparent and is not beautiful.

Carbon materials are generally used as carriers at the communication port. Based on the chemical and physical properties of carbon, it is not subject to friction, so the stability is not good enough.

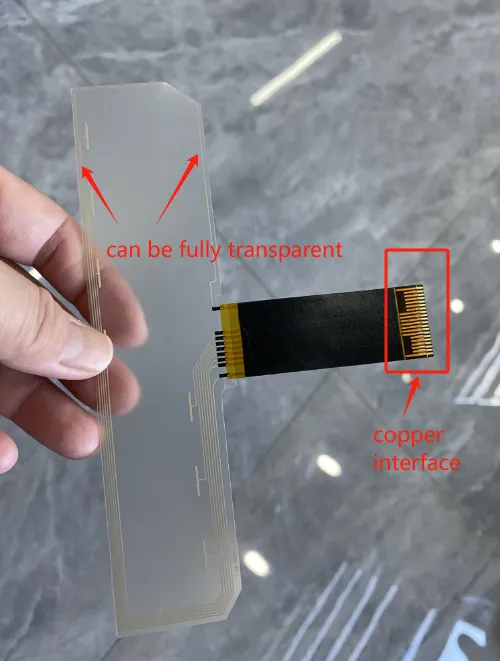

Functional sheet of copper FPC: This functional sheet is also suitable for touch screens. Unlike the integrated PIN sensor, this functional sheet is equipped with a copper communication interface at the communication interface. We already know that the material of the functional sheet is an ITO film with resistance. The resistance during the transmission process will hinder the transmission of electrical signals. Only by minimizing the impact of resistance as much as possible can the signal be transmitted smoothly. Among them, the resistance of copper is smaller than that of silver, so relatively speaking, choosing a copper FPC will be more conducive to the conduction of electrical signals.

Advantages and disadvantages of copper FPC functional sheet:

Advantages: Since copper has low resistance, we can use ITO film on the entire touch contact surface, without using silver wire as a transmission carrier. It has good transparency and can achieve a fully transparent touch surface, which is beautiful. In addition to good conductivity, copper has high hardness. Applying it to PFC can make FPC stable and friction-resistant.

Disadvantages: The price is slightly higher.

Of course, we may also combine these two types and improve them according to the actual needs of customers to achieve the most perfect solution!

Have questions about display solutions? What you want, we make it happen. contact us!

For more information on customized solutions, please click below:

Customized circuit driver board

Customized communication interface