Full lamination technology process: Full lamination technology is to seamlessly bond the display panel and touch panel (or protective glass) together through optical glue (such as OCA or OCR).

Frame bonding technology: Also known as word-of-mouth bonding, the display panel and touch panel are bonded together through a frame tape (usually double-sided tape), leaving an air layer in the center of the panel.

Advantages of full fit

1. Reduce light reflection:Optical bonding eliminates the air layer between the display panel and the touch panel, thereby reducing light reflection, improving the brightness and contrast of the screen, and making the image clearer.

2. Improve touch sensitivity: Optical bonding closely combines the touch panel with the display panel, reducing the loss of touch signals and improving touch sensitivity and response speed.

3. Reduce the entry of dust and water vapor:Since there is no air layer, it is more difficult for dust and moisture to get inside the screen, improving the device's durability and water resistance.

4. Enhance mechanical strength: The optical bounding structure is stronger overall and can effectively improve the screen's impact and earthquake resistance.

5. The body is thinner and the frame is narrower: The optical bounding has a thinner body. The touch screen and display are bonded using optical glue, which only increases the thickness by 25μm-50μm; it is 7mm-10mm thinner than the frame.

6. Less noise interference: In addition to improving the strength of the touch screen and display panel, the full fit can effectively reduce the interference of noise on touch signals and improve the smoothness of touch operations.

Disadvantages of full lamination process: Complex process and high cost

Frame sticker technical features

1. Lower manufacturing cost: The process of frame bonding technology is relatively simple, and the cost of materials and equipment required is low, so the overall manufacturing cost is lower than that of full bonding.

2. Easy maintenance: Frame-mounted technology makes it relatively easy to disassemble and replace the display or touch panel during maintenance, reducing the difficulty and cost of maintenance.

Summary of differences:

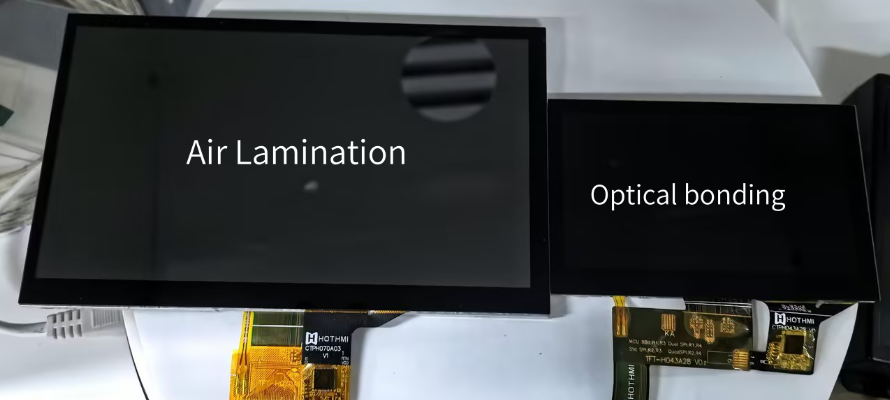

Project | Optical bonding | Air Lamination |

optical effects | Low reflectivity and better display effect | There may be poor display effects caused by light reflection |

Touch performance | high sensitivity | Touch performance is slightly poor |

Durability | Optical bonding screens are better at dustproof, waterproof and shockproof | Slightly worse |

Cost and difficulty of manufacturing | High cost and complex process | Easy maintenance and low cost |

body shape | Thin body | Larger and thicker |

Noise immunity | smaller | Difference |