Customized common cables: multi-PIN cables, FFC and FPC

Multi-pin cable:

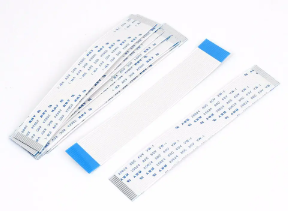

FFC cable

Customize FFC flat cables with different pitches: 0.5mm、1.0mm、1.25mm、1.27mm、2.0mm、2.54mm

Customize FFC flat cables of different thicknesses: 0.12mm、0.136mm、0.138mm、0.155mm、0.17mm、0.21mm、0.22mm、0.26mm、0.3mm

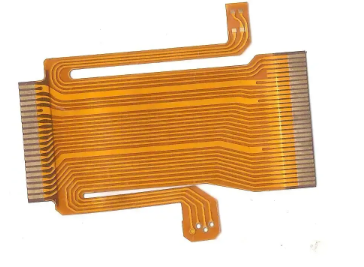

FPC cable

1. Customize FPC with different layers: single layer, double layer, multi-layer

A single-layer FPC flexible circuit board is an FPC circuit board with a single-layer substrate. It usually has only one side of copper foil, and the circuit can only be laid out on this side of copper foil. In the design and manufacture of FPC, the manufacturing process of a single-layer circuit board is relatively simple and has a wide range of applicability, so it is also one of the most common FPC circuit boards.

A double-layer FPC flexible circuit board is an FPC circuit board with two layers of substrate. Usually, both single-sided copper foil and double-sided copper foil may be used for circuit layout. Compared with a single-layer circuit board, a double-layer circuit board has a more flexible circuit design space and more circuit layout options.

A multi-layer FPC flexible circuit board is composed of multiple layers of flexible substrates and circuit layers. Usually, a multi-layer FPC board contains three to six layers of circuit layers, with an insulating layer in the middle and the outermost layer covered with a protective layer or a copper clad layer. Multi-layer FPC boards have the advantages of high reliability, high fault tolerance and high stability, and they are widely used in the application field of high-performance electronic products.

2. Customize FPC with different substrates

PI FPC: Polyamide (PI) FPC flexible circuit board is a flexible circuit board made of polyamide (PI) material as the base material. This material has high temperature resistance and excellent mechanical properties, and is suitable for high-density circuit design.

PET FPC: Polyester film (PET) FPC flexible circuit board is a flexible circuit board made of polyester film as the base material. This material is often used in some low-cost, lightweight and portable devices, such as smart bracelets, headphones, mobile power supplies, etc.

PEN FPC: A flexible electronic circuit board made of polyethylene terephthalate (PET) and polyethylene-naphthalate (PEN) materials. It can be used in electronic devices, computer accessories, LCD displays, touch screens, backlight panels, LEDs and other products.

FPC with adhesive layer: FPC with adhesive layer refers to a flexible circuit board with an adhesive layer. Its base material is usually made of polyimide film or polyamide nitrile film, and the adhesive layer is a layer of adhesive coated on the base material.

FPC without adhesive layer: FPC without adhesive layer refers to a flexible circuit board without an adhesive layer, and its base material is usually made of materials such as polyester film, polyimide film or polyamide nitrile film.

High-density FPC: High-density FPC flexible circuit board refers to a flexible circuit board with a higher line density. It usually uses special materials and manufacturing processes to achieve the arrangement of more wires and tightly arranged connectors in a smaller space.

Low-density FPC: Low-density FPC flexible circuit board refers to a flexible circuit board with a lower line density. Unlike high-density FPC flexible circuit boards, low-density FPC flexible circuit boards usually use a simpler manufacturing process and relatively lower manufacturing costs.

Hot Display is an expert in display manufacturing. In addition to providing you with a variety of high-quality display solutions and manufacturing high-quality displays, we can also "tailor-make" various cables for you to meet a variety of different product requirements!

For more information about custom cables, please contact us directly!