In the production of liquid crystal displays, cleaning refers to the process of removing various harmful impurities or oil stains adsorbed on the glass surface. The cleaning method is to use various chemical reagents and organic solvents to react and dissolve the impurities and oil stains adsorbed on the glass surface, or to use physical measures such as ultrasound, heating, and vacuuming to desorb (or desorb) the impurities from the glass surface, and then rinse with a large amount of high-purity hot and cold deionized water to obtain a clean glass surface.

Cleaning and drying process principles

ITO conductive glass is easily contaminated by impurities such as dust and grease during production, packaging and transportation. Glass that has not been cleaned cannot guarantee the process quality requirements. These impurities rely on static electricity to adsorb on the glass surface and are relatively easy to remove. There are many ways to clean it. It can be cleaned with organic solvents, alkaline solution plus ultrasonic cleaning, or neutral detergents. They all have their own advantages.

After cleaning, the surface of the glass is stained with cleaning liquids such as water or organic solvents, which will have an adverse effect on subsequent processes. Especially in the photolithography process, it is easy to produce problems such as floating glue, drilling, and unclear graphics. Therefore, the cleaned glass must be dried. The commonly used methods at present include drying, spin drying, organic solvent dehydration, and air knife drying.

1. Process

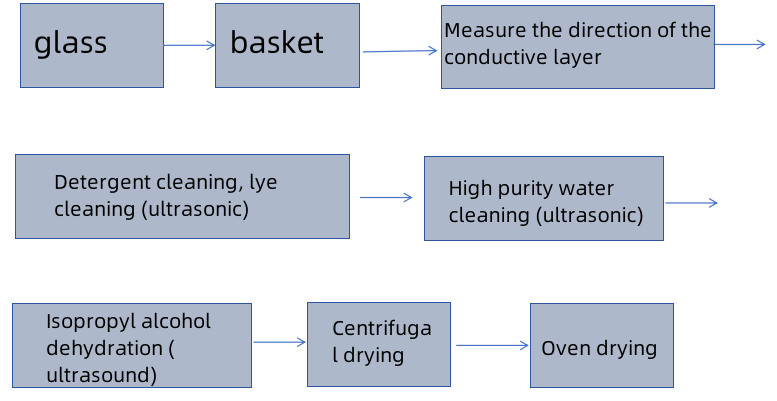

The cleaning and drying process is shown in Figure 1.

(Figure 1.)

In the cleaning and drying process, the first process is to unpack the glass substrate. At this time, according to the production process requirements, the square resistance and other indicators of the ITO glass raw materials should be checked to see if they meet the process technology conditions. In most of the actual production processes, the conductive layer (ITO film) of the glass substrate is facing up. In order to ensure this, it is also necessary to conduct inspections. The simple way is to use the ohm block of the multimeter to test whether the glass surface is conductive. The deflection of the multimeter pointer indicates that the surface is the IO surface. On the contrary, the pointer does not move, indicating that the surface is not the ITO surface.

For TN type liquid crystal box production lines, sometimes it is necessary to cut ITO glass into small pieces and put them in the basket, and the basket is a plastic basket; for STN type liquid crystal box production lines, ITO glass does not need to be cut and directly loaded into the stainless steel basket.

2. Precautions

Organic solvents commonly used in cleaning include ethanol, acetone, isopropanol, etc. These solvents have relatively low ignition points and will burn if the temperature is too high or when exposed to open flames. Therefore, the following matters should be noted when using them:

》Organic solvents must be stored in a cool place and not near open flames

》Organic solvents are volatile and have certain toxicity. When using them, try to avoid contact with the skin or inhalation

》If a fire occurs accidentally, it should be handled properly. For toluene that is difficult to dissolve in water, water cannot be used to extinguish the fire. Only sand, foam extinguisher, and carbon dioxide fire extinguisher can be used to extinguish the fire

Cleaning and drying equipment

1) Cleaning Cleaning is an important operation that needs to be repeated many times after the glass substrate is inspected, etched, and rubbed. In the production of TN-type LCD screens with low automation, the operator changes the entire basket of glass substrates from one slot to another for cleaning.

On the automated STN-type LCD production line, the cleaning operation is carried out in a closed device. The operator places the entire basket of glass substrates in a fixed position on the equipment. The conveying equipment automatically extracts the glass one by one and cleans it while conveying it on the conveyor belt. In the cleaning process before and after friction, the entire basket is also cleaned, and the basket containing the glass is changed from one slot to another by an automatic device.

2) Drying

In the production of TN-type LCD screens, after cleaning in the entire basket, the entire basket of glass is generally sent to a centrifugal dryer for high-speed rotation, dehydrated by centrifugal force, and then sent to an oven for drying.

On the automated STN-type LCD production line, after cleaning in a single-piece manner, compressed dry clean air or compressed dry clean gas is sprayed on the glass for forced drying, and then sent to a clean oven for drying.