Hot Display's product production is standardized, and each step follows the rules of production quality control, aiming to manufacture high-quality and cost-effective products. They are delivered to customers in strict accordance with delivery standards.

Chinese terminology | Japanese terminology | Definition and content |

Arrange | Seiri | Organize your materials to keep only the essential items needed to complete your tasks. (This involves reviewing all the contents of your workspace to determine what is needed and what can be removed. Everything that is not used to complete your workflow should leave the workspace.) |

tidy up | Seiton | Make sure everything is organized and that each item has a designated place. Organize all items left at the workplace in a logical manner to make it easier for workers to complete their tasks. This often involves placing items in ergonomic locations where people don't need to bend over or make extra movements to reach them. |

clear up | Seiso | Clean the work area regularly to keep the floor and equipment clean. Check the condition of equipment and tools during cleaning and perform maintenance and repairs in a timely manner. Designate cleaning personnel and cleaning areas to ensure that each area has a dedicated person in charge. |

Clean up

| Seiketsu | Maintain the results of tidying, organizing and cleaning, and form standardized operating procedures. Develop and promote work standards and cleaning procedures. Provide 5S training to employees to improve the awareness and participation of all employees. Regularly check and evaluate the implementation of 5S to ensure standardized implementation. |

literacy | Shitsuke | Cultivate employees' habit and self-discipline of complying with and maintaining 5S standards. Continue to educate and train employees on 5S concepts and practices. Encourage employees to actively participate in 5S activities through reward and recognition mechanisms. Integrate 5S concepts into corporate culture to form long-term behavioral norms and habits. |

The ISO 9000 series of quality management systems (QMS) is a set of standards that helps organizations ensure they meet customer needs and other stakeholder needs within the legal and regulatory requirements associated with their products or services. ISO 9000 addresses the fundamentals of a quality management system, including the seven quality management principles that form the basis of the series of standards. ISO 9001 deals with the requirements that must be met by organizations that wish to meet the standard.

Third-party certification bodies provide independent confirmation that an organization meets the requirements of ISO 9001. More than one million organizations worldwide have been independently certified, making ISO 9001 one of the most widely used management tools in the world today.

Reasons for use

The global adoption of ISO 9001 can probably be attributed to a number of factors. Early on, ISO 9001 requirements were intended to be used by purchasing organizations as a basis for contractual arrangements with their suppliers. This helped to ensure product quality by establishing basic requirements for suppliers, thereby reducing the need for "supplier development."

Principle 1 – Customer Focus

Organizations are dependent on their customers and therefore should understand current and future customer needs, should meet customer requirements and strive to exceed customer expectations.

Principle 2 – Leadership

Leaders establish unity of purpose and direction of the organization. They should create and maintain an internal environment that enables people to fully participate in achieving the organization's goals.

Principle 3 – People Involvement

People at all levels are the essence of the organization and their full involvement enables their capabilities to be used for the benefit of the organization.

Principle 4 – Process Approach

When activities and related resources are managed as a process, the desired results can be achieved more effectively.

Principle 5 – Improvement

Improvement of the overall performance of the organization should be a permanent goal of the organization.

Principle 6 – Evidence-Based Decision Making

Effective decision making is based on the analysis of data and information.

Principle 7 – Relationship Management

An organization and its external providers (suppliers, contractors, service providers) are interdependent and mutually beneficial relationships enhance the ability of both parties to create value.

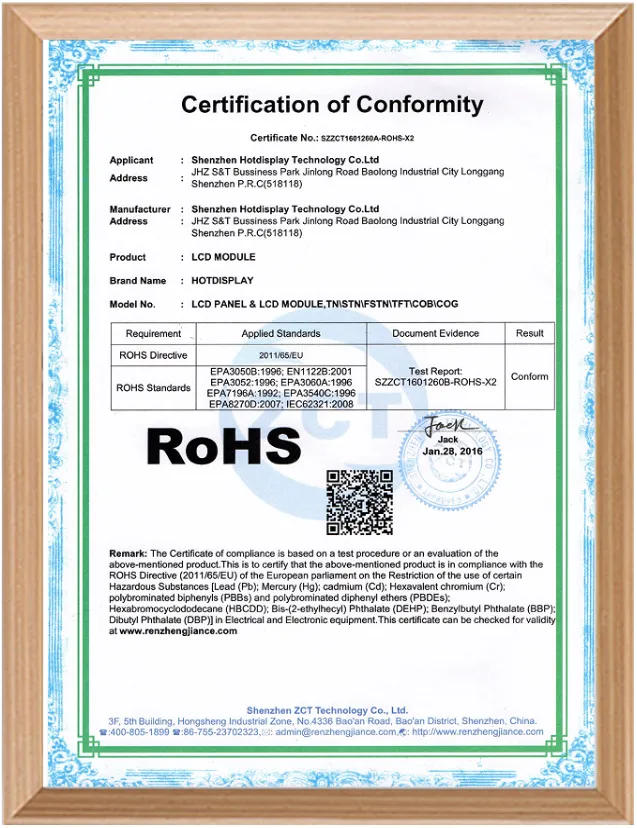

RoSH Certification:![]()

RoHS certification is a mandatory standard established by EU legislation. Its full name is "Restriction of Hazardous Substances". This standard has been officially implemented since July 1, 2006. It is mainly used to regulate the material and process standards of electronic and electrical products to make them more beneficial to human health and environmental protection.

Specifically, the RoHS Directive restricts the use of the following hazardous substances in electrical and electronic equipment:

Lead (Pb)

Mercury (Hg)

Cadmium (Cd)

Hexavalent chromium (Cr6+)

Polybrominated biphenyls (PBB)

Polybrominated diphenyl ethers (PBDE)

According to the RoHS directive, the content of the above substances in electronic and electrical equipment shall not exceed the prescribed maximum limit value. The introduction and implementation of this directive has prompted the electronic and electrical industry to gradually reduce or eliminate the use of hazardous substances, promoted green and environmentally friendly technological innovation, and helped reduce the harm of electronic waste to the environment and human health.

Enterprises need to pass the RoHS certification process to prove that their products do not contain or contain only a very small amount of the above hazardous substances. RoHS certification is not only applicable to the EU market, but also affects the design and manufacturing of electronic and electrical products around the world, and has become one of the important environmental protection standards widely recognized internationally.

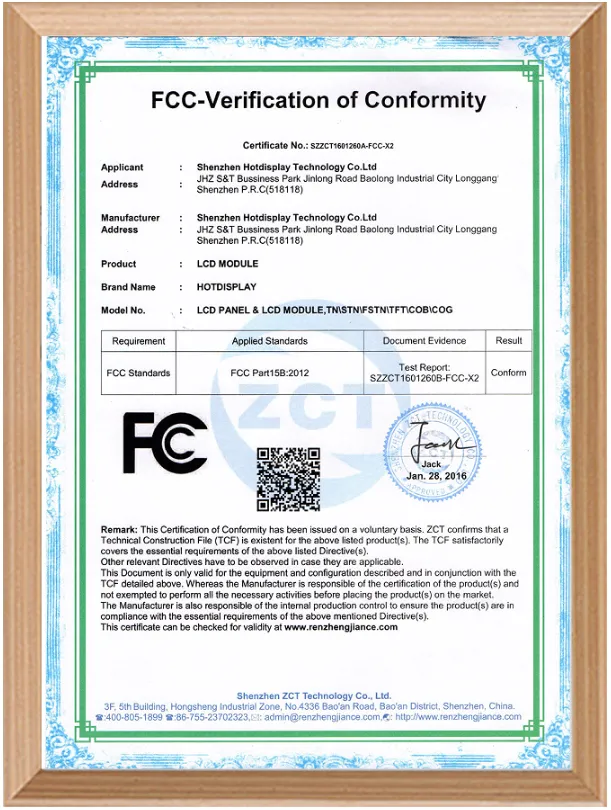

FCC:

The FCC (Federal Communications Commission) is an independent agency of the U.S. government responsible for regulating domestic and international communications. Founded in 1934, the FCC's responsibilities include the management and supervision of television, radio, satellite, telephone, radio, the Internet and other communications.

The FCC's main responsibilities include:

Regulate the radio spectrum: Manage and allocate radio spectrum to ensure that radio, television, mobile phones and other wireless communication devices do not interfere with each other.

Develop communication standards and rules: Develop and enforce technical standards and operating rules for the communications industry to ensure the reliability and security of communication networks.

Enforcement and compliance: Monitor and ensure that communications equipment and services comply with federal regulations and impose penalties for violations.

Consumer protection: Protect the rights of consumers, including preventing unfair charges and privacy violations, and ensure that communications services are fair and transparent.

Promote competition: Promote competition in the communications industry through antitrust regulations and other measures, and encourage technological innovation and service improvements.

Public safety: Ensure smooth communications in emergencies and support emergency response systems and disaster recovery.

FCC certification means that electronic products that meet FCC standards have been tested and reviewed to ensure that they do not cause harmful interference to public communication networks and comply with relevant technical specifications. Many electronic products need to pass FCC certification before entering the US market, such as radio equipment, computers, mobile phones, etc. This certification ensures the safety, reliability and compatibility of the product, thereby maintaining the overall quality of the communication network.

Hot Display More certification specifications (link)