Basic structure

At present, OLED is divided into two types: small molecule and polymer. Small molecule OEL devices using dyes or pigments as materials are generally called OLEDs, while OEL devices using conjugated polymers as materials are called PLEDs (Polymer Light Emitting Displayor Diode).

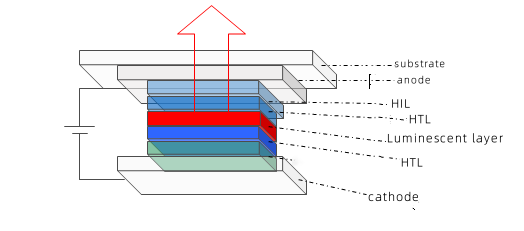

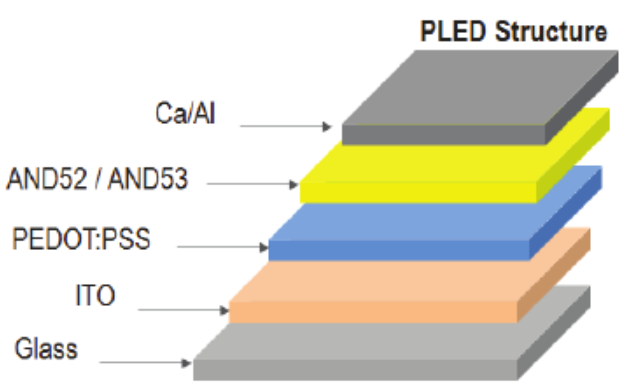

Both small molecule OLEDs and polymer OLEDs (i.e. PLEDs) use a thin, transparent, conductive indium tin oxide (ITO) as the anode, like a sandwich structure, with the organic light-emitting material layer sandwiched between the anode and the metal cathode. The organic film (light-emitting layer) of the small molecule OLED is a multi-layer structure, namely the hole transport layer (HTL), the light-emitting layer (EL) and the electron transport layer (ETL), as shown in Figure 1; the organic film of the PLED is a single-layer structure, as shown in Figure 2.

(Figure 1)

(Figure 2)

Luminescence principle

Driven by a certain voltage, the electrons generated by the cathode and the holes generated by the anode of the OLED are respectively injected into the light-emitting layer (for small molecule OLEDs, the electrons and holes are first injected into the electron and hole transport layers, respectively, and then migrate to the light-emitting layer through the electron and hole transport layers). In the light-emitting layer, the electrons and holes meet and recombine, and emit visible light due to the energy band transition. The radiated light can be observed from the ITO transparent anode side through the glass (or plastic) substrate, and the bright metal plate cathode also acts as a reflector. The color of the light emitted is different due to the different composition of the light-emitting layer material. Therefore, by selecting different light-emitting materials, red, blue, and green light can be obtained to achieve full-color display.

The light-emitting process of OLED can be summarized into the following 4 steps.

(1) Carrier injection (electrons and holes are injected from the cathode and anode respectively).

(2) Carrier transport (injected electrons and holes are transported to the light-emitting layer).

(3) Carrier recombination and exciton formation.

(4) Exciton decay and emit photons

The actual structure of OLED is very simple: first, a transparent ITO anode is evaporated on a glass or transparent plastic substrate, and a passivation layer is covered on top to increase stability; on the passivation layer are P-type and N-type organic semiconductor materials (electron and hole transport layers), and their contact surface is the organic light-emitting layer; the top is a magnesium-silver alloy cathode. These coatings are thermally evaporated onto the substrate, and the thickness is very small, only 100-150nm, less than 1% of a hair, while the thickness of traditional LEDs is at least in the micron level. As long as a DC voltage of 2~10V is applied between the two electrodes of the OLED, this organic PN junction can emit relatively bright light. At present, the green light brightness emitted by OLED is relatively high, reaching 7~10lm/W, which is almost the same as that of incandescent bulbs.

OLED colorization

Full color display is an important indicator of whether the display is competitive in the market, so many full color technologies are also applied to OLED displays. According to the type of panel, there are usually three types: RGB pixel independent light emission, light color conversion (Color Conversion) and color filter film (Color Filter Layer).

1. RGB pixel independent light emission (RGB three-primary color light emission method) is the most widely used color mode at present.

It uses precise metal shadow mask and CCD pixel alignment technology to first prepare the red, green and blue three-primary color light emission centers, and then adjust the mixing ratio of the three color combinations to produce true color, so that the three-color OLED elements can emit light independently to form a pixel. The key to this technology is to improve the color purity and light emission efficiency of the light-emitting material, and the metal shadow mask etching technology is also crucial.

With the colorization, high resolution and large area of OLED displays, the metal shadow mask etching technology directly affects the quality of the display panel, so it puts forward more stringent requirements on the size accuracy and positioning accuracy of the metal shadow mask graphics.

2. Light color conversion method

Light color conversion is a method of combining blue light OLED with light color conversion film array. First, a device that emits blue light OLED is prepared, and then its blue light is used to excite the light color conversion material to obtain red light and green light, thereby obtaining full color. The key to this technology is to improve the color purity and efficiency of the light color conversion material. This technology does not require metal shadow mask alignment technology, only requires evaporation of blue light OLED components, and is one of the most promising full-color technologies for future large-size full-color OLED displays. However, its disadvantage is that the light color conversion material easily absorbs blue light in the environment, resulting in a decrease in image contrast, and the light guide will also cause a decrease in picture quality.

Currently, Japan's Idemitsu Kosan, which has mastered this technology, has produced a 10-inch OLED display.

3. Color filter film method

This technology uses white light OLED combined with color filter film. First, a device that emits white light OLED is prepared, and then three primary colors are obtained through the color filter film, and then the three primary colors are combined to achieve color display. The key to this technology is to obtain high-efficiency and high-purity white light. Its production process does not require metal shadow mask alignment technology, and can use mature LCD color filter film production technology, so it is one of the potential full-color technologies for future large-size full-color OLED displays. However, using this technology, the light loss caused by passing through the color filter film is as high as 2/3. Currently, Japan's TDK Company and the United States' Kodak Company both use this method to make OLED displays.

The three full-color technologies for making OLED displays, RGB pixel independent light emission, light color conversion and color filter film, each have their own advantages and disadvantages.

The following table compares three methods of achieving colorization of OLED.

Methods | Three-primary-color luminescence method | Color filter film method | Light color conversion method |

Color purity | Excellent | Good | Good |

Luminous efficiency | High | Low | Fair |

Size | Average | Large size possible | Large size available |

Fineness | Average | Good | Good |

Cost | High | Low | Medium |

Hot Display has been focusing on display research for more than 20 years. In response to market demand, we have also developed OLEDs of different sizes and colors.

128x64 2.4 inch monochrome display blue OLED graphic OLED module SSD1309

▶Model: HTM-OLED2.42-SPI-B

▶Size: 2.42 inches diagonally

▶Display format: 128x64 pixels

▶Display type: Graphic OLED module

▶Display color: Monochrome blue

▶Appearance (mm): 72x43x7.02

▶AA (mm): 55.01x27.49

▶Power supply voltage: 3.3V

▶Interface: SPI

▶Backlight brightness: 90cd/m2

▶Compatibility: Arduino

▶Controller model: SSD1309

▶Operating temperature: -40°C~80°C

▶Storage temperature: -40°C~90°C

▶New function: EMI shielding

▶Read more

1.5 inch 128x128 Yellow Graphic OLED Module Monochrome Display SH1107

▶Model: HTM-OLED 1.5-SPI-Y

▶Size: 1.50 inches diagonal

▶Display format: 128x128 pixels

▶Display type: Graphic OLED module

▶Display color: Monochrome yellow

▶Appearance (mm): 33.9x37.3x1.44

▶AA (mm): 26.855x26.855

▶Supply voltage: 3.3V

▶Interface: SPI

▶Backlight brightness: 100cd/m2

▶Compatibility: Arduino

▶Controller model: SH1107

▶Operating temperature: -40°C ~ 85°C

▶Storage temperature: -40°C ~ 90°C

▶New features: EMI shielding

1.3 inch 128x64 blue graphic OLED module monochrome display SSD1306

▶ Model: HTM-OLED1.30-SPI-B

▶ Size: 1.30 inches diagonal

▶ Display format: 128x64 pixels

▶ Display type: Graphic OLED module

▶ Display color: Monochrome blue

▶ Dimensions (mm): 35.4x33.5x5.0

▶ AA (mm): 29.42x14.70

▶ Supply voltage: 3.3V

▶ Interface: SPI

▶ Compatibility: Arduino and similar development boards

▶ Controller model: SSD1306/SH1106

▶ Operating temperature: -40°C ~ 85°C

▶ Storage temperature: -40°C ~ 90°C

▶ Special features: EMI shielding

0.66" 64x48 White Graphic OLED Monochrome Display SSD1315

▶ Model: OLED-H066-SPI-W

▶ Size: 0.66 inches diagonal

▶ Display format: 64x48 pixels

▶ Display type: Graphic OLED

▶ Display color: Monochrome white

▶ Dimensions (mm): 16.42x16.9x1.25

▶ AA (mm): 13.42x10.06

▶ Supply voltage: 3.3V

▶ Backlight brightness: 190cd/m2

▶ Interface: 8-bit 8080 parallel, 4-wire SPI, I2C

▶ Compatibility: Arduino and similar development boards

▶ Controller type: SSD1315

▶ Operating temperature: -40°C ~ 85°C

▶ Storage temperature: -40°C ~ 85°C

▶ Added function: EMI shielding

All sizes above are available with blue, yellow or white text.

For more OLED related products, please contact us directly!