What is the aging test of display screen?

Display aging test is a test method used to evaluate the performance and reliability of display screens. Its purpose is to discover and solve problems that may occur in actual use of the display screen by simulating long-term use and various environmental conditions.

Why do we need to do aging test?

LED aging test is a very important link in product quality control. LED products can improve their performance after aging, and help stabilize the performance of later uses. LED aging test is a measure adopted based on the characteristics of the product's failure rate curve, namely the bathtub curve, to improve product reliability.

Aging testing can bring us the following benefits:

Reliability assessment: Ensure the stability and reliability of the display screen during long-term use.

Quality control: Detect potential defects in the manufacturing process and improve product quality.

Life prediction: Predict the service life of the display screen through accelerated aging testing.

Performance optimization: Discover and solve performance problems of the display screen under different conditions.

Contents and steps of aging test

1. Inspection:

Check that all modules are installed correctly

Check whether there is short circuit or mixed connection in the electrical system

Check whether the module is installed flat and the seams are neat

Check whether the appearance is intact and whether there are bumps and scratches

2. Turn on the power supply for testing

3. Index test

During the test, monitor the performance parameters of the display screen in real time and record the data.

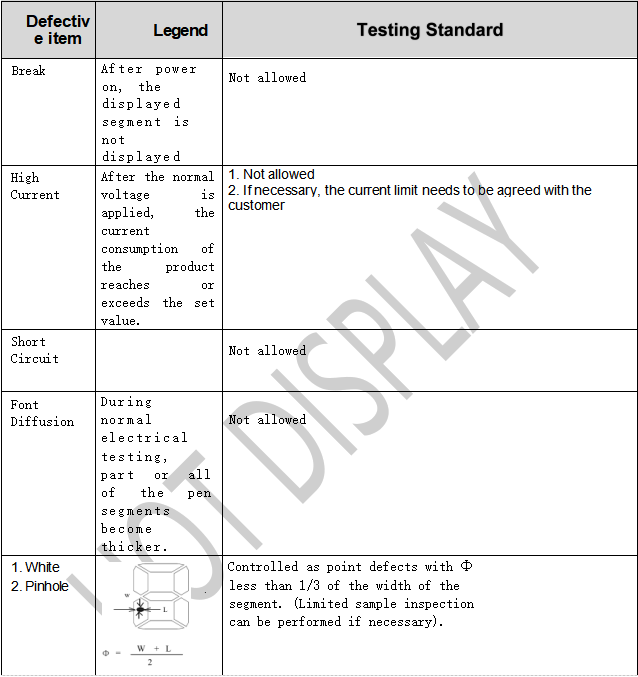

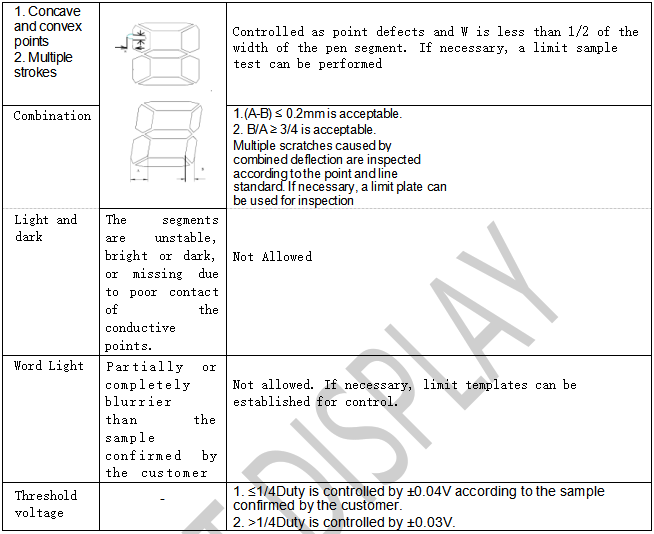

Various tests and requirements:

Products with no display, missing lines, flickering, dim display, ghosting, etc. are defective products and need to be returned to the factory for review!

4. Analysis and evaluation

Products that do not meet the standards need to be evaluated for reasons, improved methods, and retested after improvements until they meet the standards.

5. Test report:

Generate a detailed test report including test methods, conditions, results and analysis.

Improvement measures: Based on the test results, make product improvement suggestions to improve the quality and reliability of the display.

6. Notes

The aging test must be supervised by someone, and any problems found should be reported to the engineering manager for processing.

Hot Display's aging test can select A, B or C inspection standards according to the actual needs of the product.

According to the product service plan, the degree of product aging can also be selected:

High-end: full-line aging, warranty period of 3 years.

Mid-range: sampling aging, warranty period of 1 year.

Low-end: no aging, warranty period <= 3 months

Application Scope

Display aging test is widely used in the R&D and production of various display devices, including:

Consumer electronics: such as smartphones, tablets, TVs, etc.

Industrial display equipment: such as medical displays, industrial control screens, etc.

Commercial display equipment: such as advertising displays, information display screens, etc.

Through aging testing, the reliability and durability of the display screen in various usage environments can be ensured, thereby improving the overall product quality and user satisfaction.

Hot Display is very strict in product monitoring. According to customer needs, we can selectively conduct aging tests before the products leave the factory. We can choose full inspection or sampling inspection. The aging time can also be required according to the needs, and the relevant data to be recorded, etc. We do our best to meet the needs of customers and provide first-class service quality!

Regarding Hot Display's testing items, please click the following link or contact us directly!