What is LCD?

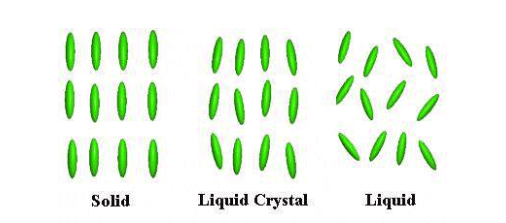

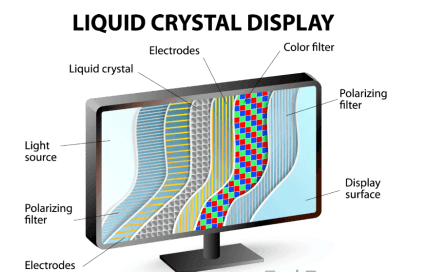

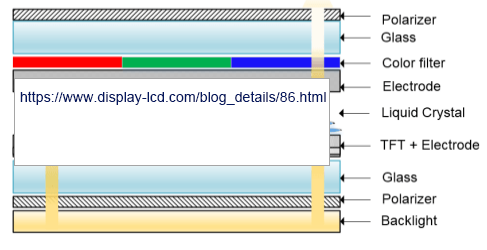

LCD panels can be classified as flat panel displays. What differentiates them from other viewing technologies is the layer of LCD material inside them. In this thin layer, liquid crystal molecules are arranged between two glass substrates. The inner surface of each substrate has electrodes to control carriers such as electrons, which then interact with the liquid crystal, creating an electric field in the liquid crystal. This in turn can change the arrangement of the crystal or the overall behavior of the molecule. On the opposite side of the substrate, a polarizer is used to control the level of passing light, thereby affecting the overall image of the screen.

How does an LCD monitor work?

Unlike CRT monitors, LCD monitors do not emit their own light, so they require a light source: a backlight. This backlight usually consists of what is known as LED, which stands for light-emitting diode. The rear polarizer and rear substrate of the backlight enter the liquid crystal. Now, light waves can manifest themselves in many ways. The backlight used on LCD screens can be LED backlighting (LED) or CCFL backlighting (cold cathode fluorescent lamp). LED reflectors consume less power and are becoming more and more popular, while CCFLs are more suitable for large LCD screens, such as large LCD TVs. In recent years, quantum dot technology has been used to improve the contrast of LCDs. )

The electrodes are the controlling factor for the behavior of the liquid crystal and therefore the behavior of the light. If current is or is not directed to the crystal layer, light may or may not be able to pass through the liquid crystal in a way that allows it to pass through the polarizer. Because of this effect, electrodes in LCDs are often made of indium tin oxide (ITO). ITO has good electrical conductivity and can also be processed into transparent electrodes, which is crucial to the appearance of today's displays.

The effect of electrodes on liquid crystal orientation depends on the orientation method used. For example, when no electric field is present, twisted nematic liquid crystals exhibit a twist direction, which polarizes light passing through the layer. When an electric field is fully applied to the electrodes, the twist straightens out and no longer polarizes light, so no light passes through. In each alignment type, the electrodes are placed differently within the structure, changing the properties of the display such as viewing angle width, power consumption, and response time. Despite these different arrangements, the purpose of the liquid crystal layer is the same: to polarize light so that it travels across the surface of the display. By polarizing the light transmitted from the backlight, the liquid crystal molecules determine how much light passes through the polarizing filter, whether all, none, or some of the light.

Groups of pixels are combined under a pixel, and the RGB colors are mixed to create a pixel color, which is then combined with other pixels to create the image seen on the display device.

How are LCD screens made?

To build an LCD, two glass substrates need to be prepared. On a substrate, ITO is typically deposited to form a transparent but conductive layer (electrode layer). Next silicon is deposited on top of the ITO layer along with the transistor components. On another layer, color filters are made using RGB color dots. A small amount of liquid crystal is then dropped into the transistor cell made from the first piece of glass, and is used as glue to precisely align the transistor cell with the color filter when the two glass substrates are brought together. Finally, add polarizing film to both layers.

The structure of LCD displays needs to be prepared for video sustainability. In sustainability, the deposition of ITO is a normal form of transparent conductive capability (electrode capability). Silicide is deposited on the ITO capacitor of the transistor assembly. In addition to color filters, RGB color filters can also be used.

What are the types and uses of LCD?

Since LCD displays were first developed, the matrix technology that organizes communication between pixels and the display's general signals has evolved to allow for higher resolution, faster and clearer displays. Before the development of active matrices, passive matrices were used. This kind of passive matrix LCD does not use active drive circuits to maintain the information of the pixels, and only sends signals when the image needs to be refreshed. This can cause the display to be slow and blurry when the displayed image changes or moves. However, the entrance must be positive. PadRIX monitors have revolutionized the display industry. Moving images are now clearer and more responsive to changing images, resulting in a higher quality display. Active matrix liquid crystal displays (AMLCDs) have become the dominant technology for high-resolution screens such as computer monitors, televisions, and smartphones due to their attractiveness to consumers due to the active and independent maintenance of the driver circuitry within each pixel.

AMLCDs are most commonly constructed from thin film transistors (TFTs). Transistors in TFT LCDs are able to actively maintain signals within a pixel without disturbing adjacent pixels, making them an important component of most AMLCDs. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between layers of transparent conductive ITO.

As mentioned before, there are various ways to arrange liquid crystal layers, and each of these techniques can create a different type of LCD. For example, LCD monitors, being one of the cheaper but faster options, have become very useful in gaming monitors that require fast graphics refresh rates and response times.

LCD technology has also found use in the automotive industry (car dashboards and screen displays) and the medical industry (radiology imaging).

LCD Technology Comparison: Then and Now

As mentioned earlier, LCDs rely on backlighting to illuminate the display and its pixels. This has been the case since LCDs were first created in the 1960s. A few decades later, monitors were quite limited in size and resolution. Colors are not as dynamic.

In the 1980s, larger displays were manufactured, such as the first 14-inch full-color TFT LCD. Since then, technology has continued to rapidly evolve into what we see today, with ever-improving smartphones and TV screens.

The display properties and potential of organic light-emitting diodes (OLEDs) have grown significantly in recent years. OLED displays offer advantages that LCDs do not. Using small molecules or polymers, OLEDs don't require a backlight; instead, each pixel has its own organic

light-emitting capabilities. This not only reduces OLED thickness but also allows for deeper blacks and higher contrast compared to LCDs. Structurally, however, apart from the backlight, the two displays are similar, as both can use passive or active matrices, both typically contain TFT layers, and both can be made transparent. In terms of construction, OLED has another advantage over LCD; without a backlight, it can become flexible, allowing for newer, more advanced displays like foldable smartphones.